Mild Steel Material

- home

- Mild Steel

Mild Steel Supplier, Mild Steel Properties, Mild Steel Manufacturers, Mild Steel Price, Mild Steel Manufacturers in India.

The various grades of mild steel are determined by their chemical composition which helps to determine its properties. This includes tensile strength, yield strength, hardness levels, and weldability among others. Depending on the grade chosen, mild steel can provide different levels of strength or hardness.

MS Material Stockist, Mild Steel Black Dealer, Mild Steel Material Grade, Mild Steel Composition, Mild Steel Rate, Mild Steel Suppliers in Mumbai India.

What is Mild

Steel?

Mild steel is a type of carbon steel with low carbon

content of 0.05% to 0.25%, and is one of the most commonly used materials in

manufacturing. It has excellent welding, forming, machining, and cutting properties

making it suitable for a wide range of applications. Mild steel can be found in

various forms such as pipes, tubes, sheets, plates, bars, and rods.

In terms of price per kilogram (kg), mild steel typically costs around $2-4/kg depending on its quality and grade. Furthermore, mild steel is also an affordable option relative to other metals and alloys which can cost significantly more.

Overall, mild steel is an economical metal with many beneficial properties that make it a great choice for a variety of applications. Its low cost and ease of machining make it ideal for both commercial and residential use. With its wide range of grades and forms available, mild steel can be used in many fields such as manufacturing, construction, automotive, engineering, and more.

MS Material Supplier in Mumbai, Mild Steel Cost Per Kg, MS Material Price, MS Manufacturers, MS Steel Price Today, Plain Mild Steel Exporter in India.

Products Made From Mild Steel

Socket weld Fittings

Threaded Fittings

Seamless Fittings

Welded Fittings

Check our mild steel price per kg in India with ms material specification.

Composition of Mild Steel

| Carbon (C) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Manganese (Mn) |

| 0.05% to 0.25% | 0.15% to 0.35% | 0.05% to 0.25% | 0.05% to 0.25% | 0.3% to 0.6% |

Mechanical Properties of Mild Steel Material

| Tensile Strength | Yield Strength | Elongation at Break | Hardness | Elastic modulus |

| 340-550 MPa | 165-275 MPa | 25-30% | 95-160 Brinell | 200 GPa |

Looking for mild steel prices in India? Get a free quote from Rajdhan Metal, one of the renowned manufacturers and stockists of mild steel material, Buy mild steel products at the best price.

Specialized in Following Mild Steel Products List

- Mild Steel Buttweld Fittings

- Mild Steel Equal Tee Stock

- Stockists of Mild Steel Piggable Bend

- Mild Steel Elbow Manufacturer

- Mild Steel Lap Joint Stub End

- Mild Steel Short Radius Elbow

- Plain Mild Steel Forged Plugs

- Galvanized Mild Steel Fitting

- Manufacturers of Mild Steel Fittings

- Mild Steel 45 Deg LR Elbow

- Mild Steel Industrial Fittings

- ASME B16.11 Mild Steel Bushing

- Mild Steel 90 Degree Elbow

- Mild Steel Barrel Nipples

- Low Carbon Mild Steel Equal Cross

- Mild Steel Weld Fittings Suppliers

- Fittings Material MS manufacturers in India

- Mild Steel Coupling Trader

- Mild Steel 90 Deg SR Elbow

- Exporter of Mild Steel Reducer

- MS Black Pipe Nipples Dealer

- Mild Steel Caps Distributor

- Mild Steel Union Wholesaler

- Black Mild Steel Fittings

- Mild Steel Weld Fitting Stockholder

- Black MS Class 6000 Reducing Tee

- Mild Steel 45 Degree Elbow

- Mild Steel Long Radius Elbow

Mild Steel Manufacturer

Mild Steel Price List in India

| Size | MSL Make | ISMT make | JSL Make |

|---|---|---|---|

| 1/2" | 1,323.53 | 1,316.18 | 1,330.88 |

| 3/4" | 1,102.94 | 1,095.59 | 1,110.29 |

| 1" | 955.88 | 948.53 | 963.24 |

| 1.25" | 911.76 | 904.41 | 919.12 |

| 1.5" | 808.82 | 801.47 | 816.18 |

Looking for mild steel manufacturer in India? We sell high-quality mild steel grades at low prices, including mild steel price per ton and per kg today in India.

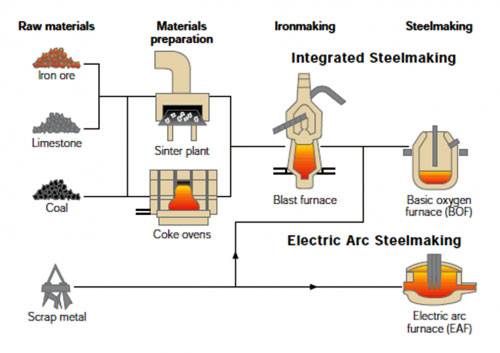

Mild Steel Manufacturing Process

The manufacturing process of mild steel involves obtaining raw materials such as iron ore, melting it in a furnace to produce molten iron, casting it into desired shapes using continuous casting, rolling it into the desired shape and size using a hot rolling process, subjecting it to heat treatment for improved mechanical properties, cooling it in a controlled manner, finishing it by adding surface coatings, cutting it into specific lengths, and bundling it for transport.