Carbon Steel Threaded Fittings

- home

- Carbon Steel

- Threaded Forged Fittings

Carbon Steel Threaded Fitting, Carbon Steel Forged Threaded Fittings, Carbon Steel Threaded Pipe Fittings, CS NPT Thread Fittings, Carbon Steel Threaded Forged Fittings Supplier in Mumbai, Carbon Steel Threaded Fittings Manufacturers in India.

Carbon Steel Threaded Forged Fittings are critical for smooth and efficient flow processes. At Rajdhan Metal, we are committed to providing our customers with top-quality fittings that meet and exceed industry standards. As a leading Carbon Steel Threaded Forged Fittings manufacturer and supplier, we offer various products catering to various industries and applications.

What are Carbon Steel Threaded Forged Fittings?

Carbon

Steel Threaded Forged Fittings are designed to connect pipes for a solid and secure fit. These pipe

connections are ideal for small diameter pipes with nominal diameter NPS 2 or smaller. They are mostly

used in low-pressure applications such as fire protection, water supply, cooling systems, etc. These

pipe fittings are valves, elbows, tees, nipples, couplings, crosses, plugs, etc. They are usually made

of high-quality steel, such as carbon, alloy, and mild steel. These fittings are available in various

thread types like NPT, BSPP, BSPT, PF, PT and MPT.

Our selection comprises fittings from leading manufacturers, ensuring that every product we offer meets stringent industry standards and regulations. This includes 2000#, 3000#, and 6000# forged carbon steel NPT threaded pipe fittings, all designed for optimal functionality and longevity. We also provide different types of fittings, such as tees, crosses, and unions, allowing you to choose the perfect solution for your piping system. Contact Us today for a free quote and get the best carbon steel threaded fittings deals.

- Carbon Steel Threaded Fittings Specifications

- Carbon Steel Thread Fitting Types

- Carbon Steel Threaded Fittings Dimensions

- Carbon Steel Threaded Pipe Fittings Pressure Rating

- Specialized in Following ASME B16.11 Threaded Carbon Steel Fittings

- Carbon Steel Threaded Fittings Price List

- Carbon Steel Threaded Fittings Weight Chart

- Different Types of Threads - CS Fittings

- Carbon Steel Threaded Fittings Industrial Applications

Carbon Steel BSP Thread Fittings, CS Threaded Fittings Suppliers, Black Steel Screw Fittings, Carbon Steel Forged Steel Threaded Fittings Supplier in India, Carbon Steel Threaded Fittings Manufacturer.

Applications of Carbon Steel Threaded Forged Fittings

Carbon Steel npt threaded fittings are used in various industries, including petrochemicals, power

generation, oil and gas, chemical plants, etc. They are ideal for high-pressure applications, such as

hydraulic systems, steam lines, and other fluid applications that require reliable and leak-proof

fittings.

Why Choose Carbon Steel Threaded Forged Fittings?

Carbon

Steel Forged Threaded Fittings differ from other fittings because of their high tensile strength,

superior corrosion resistance, and durability. They are designed to withstand extreme temperatures and

pressures, making them ideal for harsh environments. Moreover, our Carbon Steel Threaded Fittings are

easy to install and maintain, providing a long-lasting and cost-effective solution.

Price List of CS Thread Fitting, Black Threaded Forged Pipe Fitting Dimensions, ASME B16.11 3000# CS Coupling, Screwed Union, Carbon Steel Plug, NPT Thread Bushing Exporter in India.

At Rajdhan Metal we offer competitive prices for our Carbon Steel Threaded Forged Fittings without compromising quality. Our prices vary depending on the type, size, and quantity ordered. Also, One of our popular offerings is the 3" NPT Tee, a 3000# forged carbon steel pipe fitting. We can also customise our fittings to meet specific requirements and applications.

If you are looking for reliable carbon steel threaded forged fittings, Look no further than Rajdhan Metal. We guarantee customer satisfaction with our wide range of products, competitive prices, and top-notch customer service. Contact Us today for your Carbon Steel Threaded Fittings needs, and let us be your trusted supplier.

Carbon Steel Threaded Fittings Specifications

| Specifications | ASTM A105 / ASME SA105 / A350 LF 2 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Screwed-Threaded) |

| Thread | NPT, BSPT, BSPP |

| Types | Screwed-Threaded Fittings |

| Pressure Rating | Threaded End-2000lb/ 3000lb/ 6000lbs |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

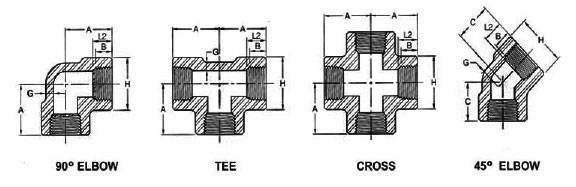

| Specialized manufacturer of | Threaded 90 deg Elbows, Cross, Inserts, and Unions, Caps, 45 degree Elbows, Nipples, Couplings, Tees, Plugs, Equal Tees, Reducing Tees |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Carbon Steel Threaded Fittings Types

Check Price List and Dimensions of Black Carbon Steel NPT Threaded Fittings.

Carbon Steel Threaded Pipe Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Reliable Supplier of Black Forged Steel Threaded Fittings in Mumbai, India. Check NPT fittings dimensions and BSP sizes in mm.

Carbon Steel NPT Fittings Dimensions

| Thread Of NPT Size And Pitch |

Dash Size |

Thread Male Minor Outside Daimeter |

Female ID Thread |

||

| inches – TPI | millimeter | inches | millimeter | inches | |

| 1/8 – 27 | -02 | 9,9 | 0.39 | 8,4 | 0.33 |

| 1/4 – 18 | -04 | 13,2 | 0.52 | 11,2 | 0.44 |

| 3/8 – 18 | -06 | 16,6 | 0.65 | 14,7 | 0.58 |

| 1/2 – 14 | -08 | 20,6 | 0.81 | 17,8 | 0.70 |

| 3/4 – 14 | -12 | 26,0 | 1.02 | 23,4 | 0.92 |

| 1 – 11.1/2 | -16 | 32,5 | 1.28 | 29,5 | 1.16 |

| 1.1/4 – 11.1/2 | -20 | 41,2 | 1.62 | 38,1 | 1.50 |

| 1.1/2 – 11.1/2 | -24 | 47,3 | 1.86 | 43,9 | 1.73 |

| 2 – 11.1/2 | -32 | 59,3 | 2.33 | 56,4 | 2.22 |

| 2.1/2 – 8 | -40 | 71,5 | 2.82 | 69,1 | 2.72 |

| 3 – 8 | -48 | 87,3 | 3.44 | 84,8 | 3.34 |

Carbon Steel BSP Fittings Dimensions

| Bspp and Bspt Pitch And Size |

Dash Size |

Bspt Male Thread Outside Daimeter |

Bspp Male THREAD Outside Daimeter |

Bspt Female Thread Inside Daimeter |

Bspt Female Thread Inside Daimeter |

||||

| inches – TPI | millimeter | inches | millimeter | inches | millimeter | inches | millimeter | inches | |

| 1/8 – 28 | -02 | 9,5 | 0.37 | 9,6 | 0.38 | 8,4 | 0.33 | 8,6 | 0.34 |

| 1/4 – 19 | -04 | 12,8 | 0.50 | 13,0 | 0.51 | 11,2 | 0.44 | 11,9 | 0.47 |

| 3/8 – 19 | -06 | 16,3 | 0.64 | 16,5 | 0.65 | 14,7 | 0.59 | 15,2 | 0.60 |

| 1/2 – 14 | -08 | 20,4 | 0.80 | 20,8 | 0.82 | 18,3 | 0.72 | 19,1 | 0.75 |

| 5/8 – 14 | -10 | 22,5 | 0.89 | 22,8 | 0.90 | 20,6 | 0.81 | 20,8 | 0.82 |

| 3/4 – 14 | -12 | 25,9 | 1.02 | 26,3 | 1.04 | 23,9 | 0.94 | 24,6 | 0.97 |

| 1 – 11 | -16 | 32,6 | 1.28 | 33,1 | 1.30 | 29,7 | 1.17 | 30,7 | 1.21 |

| 1.1/4 – 11 | -20 | 41,1 | 1.62 | 41,8 | 1.64 | 38,6 | 1.52 | 39,4 | 1.55 |

| 1.1/2 – 11 | -24 | 47,0 | 1.85 | 47,7 | 1.88 | 44,5 | 1.75 | 45,5 | 1.79 |

| 2 -11 | -32 | 58,6 | 2.31 | 59,5 | 2.34 | 56,4 | 2.22 | 57,4 | 2.26 |

| 2.1/2 – 11 | -40 | 74,1 | 2.92 | 75,1 | 2.95 | 71,9 | 2.83 | 72,6 | 2.86 |

| 3 – 11 | -48 | 86,6 | 3.41 | 87,9 | 3.46 | 84,6 | 3.33 | 85,4 | 3.36 |

Carbon Steel Threaded Fittings Pressure Rating

Threaded pipe fittings typically have pressure ratings of either 3000 psi or 6000 psi, depending on industry standards such as ASME B16.11, MSS SP-79/83/95, or BS 3799, and can vary dependent on the material, thread type, and size of the fitting.

| ASME B16.11 Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

Black Steel Class 3000/ 6000/ 9000 Threaded Pipe Fittings Pressure Rating

| Description | Class Designation | ||

| class 3000 fittings pressure rating | class 6000 fittings pressure rating | class 9000 fittings pressure rating | |

| 45 deg and 90 deg elbow Tee, Coupling, Crosse, Half-Coupling, End or NPT Pipe Cap |

1/2 - 4 | 1/2 - 2 | 1/2 - 2 |

| 1/2 - 4 | 1/2 - 2 | 1/2 - 2 | |

| 1/2 - 4 | 1/2 - 2 | 1/2 - 2 | |

| Pipe Size by Wall Thickness |

SCH 80 / XS | SCH 160 | XXS |

Specialized in Following ASME B16.11 Threaded Carbon Steel Fittings

- Carbon Steel Threaded Elbow for Piping Connection

- Carbon Steel Metric Threaded Fittings

- NPT Carbon Steel Threaded Fittings

- Buy Threaded Carbon Steel Pipe Fittings

- Carbon Steel Screwed Fittings Suppliers

- Carbon Steel Industrial Forged Threaded Fittings

- Carbon Steel Class 6000 Fittings

- ASME B16.11 Carbon Steel Threaded Plug

- Galvanized Carbon Steel NPT Threaded Street Elbow

- Galvanized Carbon Steel Forged Fitting

- Low Carbon Threaded Steel Fittings

- Stockists of Carbon Steel BSPT Elbow

- ASTM A350 LF2 Low Temperature Steel Thread Fitting

- BSP Carbon Steel Threaded Fittings

- Carbon Steel Threaded Fittings Stockist

- CS Threaded Galvanized Pipe Fittings

- Carbon Steel NPT Screwed Fittings

- Class 3000, Carbon Threaded Steel Fittings

- Carbon Steel Threaded Plug Wholesaler

- Carbon Steel Threaded 45 Deg Elbow

- Carbon Steel Threaded Adapter Stockholder

- High CS Class 6000 Screw Fittings

- Carbon Steel 90 Degree NPT Elbow

- Carbon Steel Screwed Pipe Fittings

- Manufacturers of CS NPT Threaded Pipe Fittings

- ASME B16.11 Black Forged Steel Threaded Pipe Fittings

- Carbon Steel BSP Threaded Forged Fittings

- Exporter of Threaded Carbon Steel Fittings

- Carbon Steel Threaded Fittings Exporter

- Cast Iron Threaded Fittings Dealer

- Carbon Steel Threaded Fittings Supplier

- CS High Pressure Forged Threaded Pipe Fittings

- Carbon Steel BSP Screwed Fittings

- Black Iron Threaded Pipe Fittings Distributor

Forged Carbon Steel Threaded Pipe Fittings Manufacturer

Carbon Steel Threaded Fittings Price List

| Product | Price |

| Custom Size 2000 LB, 1 1/2 Inch CS Screwed Elbow Price | US $ 0.3-1.0 / Piece |

| ASME B16.11 Black Threaded Fitting Price | US $ 1.00-3000.0 / Piece |

| Black Fittings Threaded Coupling Price List | US $ 2.0-60.0 / Piece |

| NPS 1/2 to 2 Cast Iron Fittings Union Male x Female Price | US $ 2.2-50.0 / Piece |

| ANSI B16.11 CS High pressure Threaded Fittings Price | US $ 1-1000 / Piece |

| Carbon Steel Threaded Hex Pipe Nipple | US $ 1.3 / Piece |

| ASTM A105 Threaded Boss Fitting Price | US $ 00.2-55 / Piece |

| 2 X 1-1/2 Inch, 3000 LB, Carbon Steel Reducing Tee Price List | US $ 4.0-60.0 / Piece |

| CS Galvanized Hex Bushing Price List | US $ 5.77 / Piece |

Carbon Steel Threaded Forged Fittings Weight Chart

| Size Product | 1/4” | 1/2” | 2” | 3/4” | 1/8” | 4” | 1” | 1-1/2” | 3/8” | 1-1/4” | 2-1/2” | 3” | |

45 Elbow |

2000 | 0.08 | 0.20 | 1.41 | 0.27 | 0.09 | 8.96 | 0.41 | 0.82 | 0.10 | 0.68 | 3.46 | 5.44 |

| 3000 | 0.12 | 0.34 | 2.23 | 0.56 | 0.09 | 8.96 | 0.94 | 2.05 | 0.24 | 1.03 | 3.71 | 5.97 | |

| 6000 | 0.27 | 0.63 | 4.37 | 1.07 | 0.11 | 11.36 | 1.27 | 2.54 | 0.39 | 2.24 | 7.01 | 14.16 | |

90 Elbow |

2000 | 0.08 | 0.25 | 1.70 | 0.35 | 0.10 | 10.21 | 0.53 | 1.06 | 0.13 | 0.82 | 3.14 | 4.81 |

| 3000 | 0.14 | 0.43 | 2.92 | 0.69 | 0.10 | 14.85 | 1.14 | 2.63 | 0.29 | 1.42 | 5.99 | 8.88 | |

| 6000 | 0.33 | 0.80 | 7.31 | 1.31 | 0.17 | 15.76 | 1.61 | 3.79 | 0.45 | 2.93 | 9.88 | 17.73 | |

Tee |

2000 | 0.12 | 0.31 | 2.16 | 0.43 | 0.13 | 14.74 | 0.69 | 1.39 | 0.17 | 1.07 | 4.11 | 6.12 |

| 3000 | 0.20 | 0.56 | 3.53 | 0.92 | 0.13 | 19.13 | 1.49 | 3.27 | 0.38 | 1.76 | 6.99 | 10.19 | |

| 6000 | 0.45 | 0.98 | 7.88 | 1.65 | 0.20 | 18.53 | 2.17 | 4.71 | 0.63 | 3.74 | 13.11 | 21.70 | |

| Cross | 2000 | 0.14 | 0.39 | 2.65 | 0.54 | 0.17 | 16.35 | 0.83 | 1.75 | 0.21 | 1.26 | 5.26 | 7.58 |

| 3000 | 0.26 | 0.72 | 4.27 | 1.06 | 0.17 | 21.93 | 1.79 | 3.93 | 0.44 | 2.13 | 8.51 | 12.45 | |

| Half Coupling | 3000 | 0.02 | 0.06 | 0.70 | 0.10 | 0.02 | 3.11 | 0.23 | 0.54 | 0.03 | 0.34 | 1.13 | 1.68 |

| 6000 | 0.06 | 0.16 | 1.70 | 0.24 | 0.07 | 5.02 | 0.45 | 0.96 | 0.09 | 0.55 | 2.10 | 3.05 | |

| Round Head Plug | 0.45 | 0.12 | 1.47 | 0.20 | 0.02 | 6.24 | 0.34 | 0.79 | 0.07 | 0.55 | 2.34 | 3.26 | |

| Red Coupling | 3000 | 0.05 | 0.13 | 1.37 | 0.19 | 0.05 | 5.44 | 0.39 | 0.99 | 0.06 | 0.68 | 2.07 | 3.08 |

| 6000 | 0.06 | 0.31 | 3.40 | 0.41 | 0.08 | 10.04 | 0.85 | 1.81 | 0.18 | 1.05 | 4.20 | 6.10 | |

| Full Coupling | 3000 | 0.04 | 0.13 | 1.40 | 0.19 | 0.05 | 6.28 | 0.45 | 1.07 | 0.06 | 0.81 | 2.29 | 3.38 |

| 6000 | 0.13 | 0.34 | 2.87 | 0.50 | 0.08 | 10.04 | 0.87 | 1.94 | 0.20 | 1.09 | 4.20 | 6.10 | |

| Cap | 3000 | 0.04 | 0.11 | 1.09 | 0.18 | 0.02 | 4.84 | 0.37 | 0.72 | 0.05 | 0.62 | 2.22 | 3.50 |

| 6000 | 0.06 | 0.26 | 2.23 | 0.40 | 0.06 | 0.71 | 0.77 | 0.09 | 0.59 | ||||

| Street Elbow | 3000 | 0.11 | 0.31 | 2.91 | 0.53 | 0.13 | 1.02 | 2.01 | 0.22 | 1.13 | |||

| Union | 3000 | 0.28 | 0.34 | 2.43 | 0.48 | 0.28 | 12.00 | 0.77 | 1.63 | 0.24 | 1.03 | 3.63 | 5.27 |

| Square Head Plug | 0.01 | 0.05 | 0.63 | 0.09 | 0.01 | 3.83 | 0.16 | 0.38 | 0.03 | 0.27 | 0.96 | 1.53 | |

| Hex Nipple | 3000 | 0.04 | 0.09 | 1.03 | 0.15 | 0.03 | 4.00 | 0.47 | 0.62 | 0.05 | 0.45 | 1.51 | 2.22 |

| Hex Head Plug | 0.03 | 0.07 | 1.03 | 0.14 | 0.01 | 5.20 | 0.22 | 0.59 | 0.05 | 0.44 | 1.80 | 2.60 | |

| Hex Head Bushing | 0.01 | 0.03 | 0.45 | 0.05 | 3.20 | 0.09 | 0.34 | 0.01 | 0.25 | 0.60 | 1.16 | ||

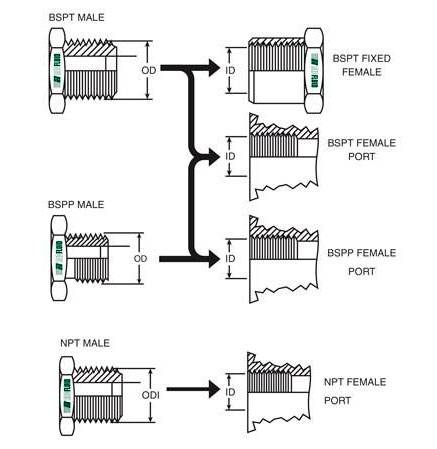

Different Types of Threads

There are different types of threads used in threaded fittings, including:

- NPT - National Pipe Thread

- BSP - British Standard Pipe (BSP, parallel)

- BSPT -British Standard Pipe Taper (BSP, tapered)

- UN/UNF (Unified National/Unified National Fine)

- Metric Thread -metric parallel, metric tapered

The specific type of thread used in a fitting will depend on the application and the standards used in that region including thread sizes, tapered and parallel, pitch sizes, and industry standards when it comes to identifying thread types.