Carbon Steel ASTM A105 Forged Nipple

- home

- Carbon Steel

ASTM A105 Carbon Steel Forged Nipples, ASME SA105N Male Female Pipe Nipple, A105 Hex Nipple, Forged CS A105 Barrel Nipple, CS SA105 Threaded Nipple, ASTM A105 Forged Steel Pipe Nipples, ASTM A105 Carbon Steel Nipple Manufacturers in India.

Rajdhan Metal is a reputable manufacturer, distributor, and trader of high-quality Carbon Steel A105 Forged Nipple. CS A105 Forged Nipple is a type of carbon steel pipe fitting that is typically used to join two pipes of varying sizes. It is a pipe reducer that is commonly used in tiny pipe sizes.

- What is a Carbon Steel Pipe Nipple ?

- ASTM A105 Carbon Steel Nipple Specification

- ASTM A105 Carbon Steel Pipe Nipple Types

- ASTM A105 Forged Threaded Pipe Nipple Dimensions

- CS Forged ASTM A105 Nipple Pressure Rating

- Specialized in Following ASME B16.11, SA105 Forged Carbon Steel Nipple

- Forged Carbon Steel ASTM A105 Nipple Price

- Forged ASTM A105 Carbon Steel Pipe Nipple Weight Chart

- ASME SA105N Nipple Industrial Applications

ASME SA 105 Steel Reducing Nipple, ASME SA 105 Forged Carbon Steel Nipple Suppliers, Supplier of ASTM A105 Forged Swage Nipple, ASTM A105 Forged Steel Nipple Manufacturer in Mumbai, Carbon Steel A105 Nipple, A105N Screwed Nipple.

What exactly is Carbon Steel A105

Forged Nipple?

ASTM A105 is a kind of carbon steel that is commonly used in forged

steel fittings. This type of nipple is resistant to high heat and pressure, as well as being strong

and ductile.

Carbon Steel A105 Forged Nipple is built with high-quality materials and cutting-edge technologies to provide the highest performance possible. After normalising, A105 has higher steel hardness and a reduced breaking propensity than A105. Carbon Steel A105 Forged Nipple not only has a comparable service life to stainless steel, but it also looks attractive and is reasonably priced. And it's more than adequate for most people's requirements. We also have anti-rust oil at our disposal.

What is Forging?

Forging is a type of pressure applied by

forging machinery to a metal blank in order to acquire specified mechanical characteristics, a certain

shape and size of the forging processing method, forging. forging and stamping) of one of the two

halves. Forging may eliminate the metal smelting process of as-cast loose flaws, such as optimising

the microstructure, and because of the unbroken metal flow, forging typically outperforms castings of

the same material in terms of mechanical qualities. Forging is more typically employed than simply

rolled plates, profiles, or welds for crucial sections with high loads and harsh operating

circumstances in connected machinery.

Features of Carbon Steel A105 Forged Nipple:

- Resistant to corrosion.

- Longevity of operation.

- Malleable.

- Heat resistance.

- High conductivity and strength.

- Perfect finish.

- Increased service life.

- Precisely planned.

ASME B16.11 High Pressure SA105 CS Forged Nipple Exporter, ASTM A105 Carbon Steel Extension Nipple, CS A105 Close Nipple, Manufacturer of Carbon Steel ASTM A105 Nipple in Mumbai, India.

ASTM A105 Carbon Steel Nipple Specification

| Specifications | ASTM A105, ASME SA 105 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Pipe Nipple Size | 1/8” NB to 4” NB |

| Thread | NPT, BSPT, BSPP |

| Connection | (male or female) Screwed-Threaded Fittings |

| Types of Nipple in Piping | Threaded Nipple, Close Nipple, Short Nipple, Shoulder nipple, Long Nipple, Running Nipple, Barrel Nipple, Swage Nipple, Hex Nipple, Pipe Nipple, Reducing Nipple |

| Pressure Rating | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | Socket Weld and Threaded Pipe Fittings, 90 deg Elbows, Cross, Inserts, and Unions, Caps, 45 degree Elbows, Nipples, Couplings, Tees, Plugs, Equal Tees, Reducing Tees |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

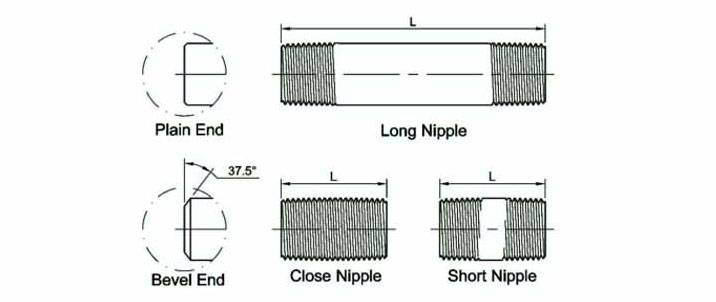

Types of ASTM A105 Carbon Steel Forged Nipple

Carbon Steel Barrel Nipple

ASME SA105 Carbon Steel Pipe Nipples

Carbon Steel Reducing Nipple

Carbon Steel Close Nipple

Carbon Steel Extension Nipple

Carbon Steel Forged Welding Nipple

View dimensions for A/SA105N NPT black steel threaded pipe nipples. We're a leading manufacturer of carbon steel forged pipe nipples.

ASTM A105 Forged Threaded Pipe Nipple Dimensions

Dimensions in Inch. (Plain End Weight (Kg)per meter)

| Nom, Pipe Size | L | Weight | ||||||

| Close Nipple | Short Nipple | Long Nipple | S40/STO | S8O/ XS | S160 | XXS | ||

|

|

|

|

|

|

|

|

|

|

|

|

7/8 | 1-1/2 |

|

0.53 |

|

|

|

|

|

|

|

|

|

|

|

|

- | |

|

|

|

|

|

|

|

1.95 | 2.55 | |

| 3/4 | 1-3/8 | 1-1/2 | 2-12 | 1.69 |

|

2.90 | 3.64 | |

|

|

|

|

|

|

|

|

5.45 | |

|

|

1-5/8 |

|

|

|

|

5.61 | 7.77 | |

| 1-1/2 | 1-3/4 |

|

|

|

5.41 | 7.25 | 9.55 | |

| 2 |

|

|

3-12 | 5.44 |

|

|

13.44 | |

| 2-1/2 | 2-112 |

|

|

8.63 |

|

14.92 |

|

|

| 3 | 2-5/8 |

|

|

|

75.27 | 21.35 |

|

|

|

|

|

|

44/2-12 | 13.57 |

|

|

|

|

|

|

2-718 |

|

4-1/2-12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5-12 |

|

|

|

|

|

(1)Thread in accordance with ASME B1.20.1

(2)weld bevel, in accordance with ASME B16- 25

(3) Weight :in accordance with ASME B36.10M Table 1.

Threaded Nipple - Close And Short Pipe Nipple Lengths

| Pipe Size | A | B | ||||||||||

| Close | Short | Standard Lengths | ||||||||||

| 1/8 | 0.405 | 0.75 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 1/4 | 0.54 | 0.875 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 3/8 | 0.675 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 1/2 | 0.84 | 1.125 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 3/4 | 1.05 | 1.375 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 1 | 1.315 | 1.5 | 2 | — | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 1 ‘1/4 | 1.66 | 1.625 | 2 | — | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 1 1/2 | 1.9 | 1.75 | 2 | — | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 2 | 2.375 | 2 | 2.5 | — | — | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| 2 1/2 | 2.875 | 2.5 | 3 | — | — | — | — | 4 | 4.5 | 5 | 5.5 | 6 |

| 3 | 3.5 | 2.625 | 3 | — | — | — | — | 4 | 4.5 | 5 | 5.5 | 6 |

| 3 1/2 | 4 | 2.75 | 4 | — | — | — | — | — | 4.5 | 5 | 5.5 | 6 |

| 4 | 4.5 | 2.875 | 4 | — | — | — | — | — | 4.5 | 5 | 5.5 | 6 |

| 5 | 5.563 | 3 | 4.5 | — | — | — | — | — | — | 5 | 5.5 | 6 |

| 6 | 6.625 | 3.125 | 4.5 | — | — | — | — | — | — | 5 | 5.5 | 6 |

CS Forged ASTM A105 Nipple Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

Our company specializes in manufacturing high-quality carbon steel screwed pipe nipples available in both TOE and TBE configurations, with threads in BSPP or NPT standards.

Specialized in Following ASME B16.11, SA105 Forged Carbon Steel Nipple

- Carbon Steel ASTM A105 BSP Nipple

- A105 High Pressure Carbon Steel Forged Nipple

- Class 3000, 2 Inch A105 Carbon Forged Steel Nipple

- Steel Forged ASTM A105 Nipple Supplier in India

- Class 6000, 2 Inch, ASTM A105 Nipple

- CS ASME SA105N 2 in. 6000# Threaded NPT Nipple

- 1 1/4 NPS, thread End, SA105 CS Nipple

- Carbon Steel A105 TOE Pipe Nipple

- ASTM A105 Nipple Suppliers

- Steel A105 Forged Nipple Wholesaler

- Carbon Steel A105 Female Threaded Nipple

- Carbon Steel Forged A105 NPT Nipple

- 1 NPS, ASME SA105 Carbon Steel Nipple

- Carbon Steel A105 Forged High Pressure Nipple

- Carbon Steel A105 BSP Forged Nipple Dealer

- Exporter of A105 Threaded Carbon Forged Nipple

- Manufacturer of Carbon Steel Nipple

- Supplier of A105N CS NPT Nipple

- Manufacturer of Carbon A105 Threaded Nipple

- ASTM A105 Forged Nipple Manufacturer in India

- A105 Forged Steel Nipple Supplier

- ASTM A105 Carbon Steel BSPP Nipple

- ASTM A105 Black Pipe Nipple Manufacturer

- ASME B16.11 Carbon Steel SA105 Nipple

- Carbon A105 Screwed Nipple Suppliers

- Class 3000, 1 1/3 Inch ASTM A105 Nipple

- Stockists of SA 105 Forged Steel BSPT Nipple

- FNPT End, 3000#, 1/2 NPS, A105N Nipple

- Carbon Steel A105N Threaded Screw Nipple

- SA 105 Galvanized Carbon Steel Forged Nipple

- Carbon Steel A105 BSP Nipple

- Carbon Steel A105 NPT Threaded Nipple

- Forged Carbon Steel ASTM A105 Industrial Nipple

- 2000 LB, 1 1/2 Inch ASTM A105 Nipple

- Carbon Steel A105 Forged Nipple

- Forged Carbon Steel A105 Screwed Nipple

- ASTM A105N 3000lbs NPT Nipple

- Forged Steel ASTM A105 Carbon Nipple

- Buy SA 105N Carbon Steel Forged Nipple

- Carbon SA105 Male Threaded Nipple

- CS A105 Forged PBE Pipe Nipple

- Carbon Steel Forged A105 High Pressure Nipple

Forged Carbon Steel Nipple

Forged Carbon Steel ASTM A105 Nipple Price List

| Size | Class | Material | Price In US($) |

| PIPES NIPPLES: 1-1/2 X 1 NPS | Class 3000 | ASTM A105 | $1.92 |

| PIPES NIPPLES: 2 NPS X 1/2 NPS | Class 3000 | ASTM A105N | $3.15 |

| PIPES NIPPLES: 2 NPS X 1 NPS | Class 3000 | ASTM A105N | $5 |

| PIPES NIPPLES: 2 NPS X 1/3 NPS | Class 3000 | ASME SA105N | $2.87 |

| PIPES NIPPLES: 2 NPS X 1/4 NPS | Class 3000 | ASME SA105 | $4.18 |

| PIPES NIPPLES: 1 NPS X 1/2 NPS | Class 6000 | ASTM A105 | $2.40 |

| PIPES NIPPLES: 1 NPS X 1/3 NPS | Class 6000 | ASTM A105N | $3.75 |

| PIPES NIPPLES: 1 NPS X 1/4 NPS | Class 6000 | ASTM A105 | $4.15 |

ASTM A105 Carbon Steel Pipe Nipple Weight Chart

| Nominal Size | Weight/kg | ||

|---|---|---|---|

| DN | NPS | SCH80/ L=100 | SCH160 / L= 100 |

| 6 | 1/8 | 0.05 | – |

| 8 | 1/4 | 0.08 | – |

| 10 | 3/8 | 0.11 | – |

| 15 | 1/2 | 0.16 | 0.2 |

| 20 | 3/4 | 0.22 | 0.3 |

| 25 | 1 | 0.33 | 0.5 |

| 32 | 1 1/4 | 0.45 | 0.6 |

| 40 | 1 1/2 | 0.55 | 0.75 |

| 50 | 2 | 0.76 | 1.1 |

| 65 | 2 1/2 | 1.15 | 1.5 |

| 80 | 3 | 1.55 | 2.2 |

| 100 | 4 | 2.25 | 3.5 |