Carbon Steel Piggable Bend

- home

- Carbon Steel

CS Piggable Bends, Carbon Steel Long Radius Piggable Bends, Carbon Steel Piggable Pipe Bend Suppliers, CS 90 Degree Piggable Bend, Carbon Steel 45 degree Piggable Pipe Bends, ANSI B16.9 Buttweld Piggable Bend Manufacturers in India.

Rajdhan Metal is a well-known leader in the manufacturing, supplying, and exporting of Carbon Steel Piggable Bend, which is well-liked by our customers because of its tough design and endurance. Carbon Steel Piggable Bend are frequently used for dewatering applications where water is polluted with solid particles, such as raw sewage, slurry effluent, industrial waste transfer, wastewater, and so on. Carbon Steel Piggable Bend have characteristics such as high tensile strength, rigid construction, corrosion resistance, rust-free, many alternatives, strongly welded, abrasion resistant, wide range, non-corrosive, excellent strength, easy installation, and more.

- What is Carbon Steel Piggable Bend?

- CS Piggable Bends Specification

- Carbon Steel Piggable Bend Types

- Radius Table of ASTM A234 Carbon Steel WPB Seamless Piggable Bends

- Carbon Steel 16 Gauge Piggable Bend Radius

- Carbon Steel Piggable Bend Radius Chart

- Specialized in Following CS Piggable Bends

- Carbon Steel Piggable Pipe Bends Price List

- CS Piggable Bends Industrial Applications

- CS Buttweld Piggable Bends Manufacturing Process

ANSI B16.9 CS 3D BW Piggable Bend, Carbon Steel 6D Pipe Piggable Bends, Carbon Steel 180 Degree Piggable Bend, High Yield CS A860 Piggable Bend, Carbon Steel Piggable Bends Manufacturer, Carbon Steel Piggable Bends Suppliers In Mumbai.

CS Piagabble Bend is made from high-quality stainless steel supplied by reputable suppliers. These Carbon Steel Piggable Bend are made of high-quality materials and have a long life, high sturdiness, high performance, and corrosion resistance. We are able to provide an optimal assortment of Piagabble Bend with superior precision, durability, and smooth finish due to the application of innovative engineering processes and contemporary machining equipment.

Carbon Steel Piagabble Bend given by us are manufactured utilizing high-quality materials and cutting-edge technologies to ensure outstanding quality and durability. Because the CS Piagabble Bend is submerged, the pump does not need to be primed and is always ready to use. Furthermore, the given Carbon Steel Piggable Bend can be conveniently acquired from us at cost-effective prices.

Qualities of Piggable Bends:

Carbon Steel Piggable Bend is one of the most versatile aluminium alloys for general application. Alloy Steel Piggable Bend is an alloy used in the production of extrusions, which are lengthy stable-cross-section structural structures formed by pushing metal through a shaped die. Super Duplex Steel Piggable Bend is an aluminium alloy that has been predominantly alloyed with magnesium. Inconel Alloy Piggable Bend is not broken by heat treatment, but rather grows harder due to strain hardening, or cold mechanical working of the material.

Carbon Steel WPB Piggable Bend, CS SMLS Piggable Bends, Carbon Steel Piggable Bends Exporter in India, ASTM A234 WPB CS 10D Seamless Piggable Bends, Manufacturer of Low Temperature Carbon Steel Piggable Bends in Mumbai, India.

Carbon Steel Piggable Bend Specification

| Specifications | ASTM A234 & ASME SA234, ASTM A420 & ASME SA420, ASTM A860 & ASME SA860 |

| Dimensions | ASME/ANSI B16.9 / B16.28 and MSS SP-43 / SP-75 |

| Size | Seamless Pipe Bends (1/2″ – 24″), ERW / Welded / Fabricated Pipe Bends (2″ – 36″) |

| Outer Diameter | 38.0 mm – 206.0 mm |

| Wall Thickness | 1.5 mm / 2.0 mm / 3.0 mm – greater wall thickness at request |

| Bend Radius | 75 / 100 / 150 / 250 / 300 / 500 / 800 / 1,000 / 1,200 / 1,500 mm |

| Bending Radius(R) | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| DIN Pipe Bend | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| EN Pipe Bend | EN10253-1, EN10253-2 |

| Bending angle (θ) | 5°, 30°, 45°, 60°, 90°, 135°, 180° |

| Application | Electric Power, Water Disposal, Chemical Engineering, Nuclear Energy, Ship Building, Garbage Disposal, Petroleum Oil, Natural Gas |

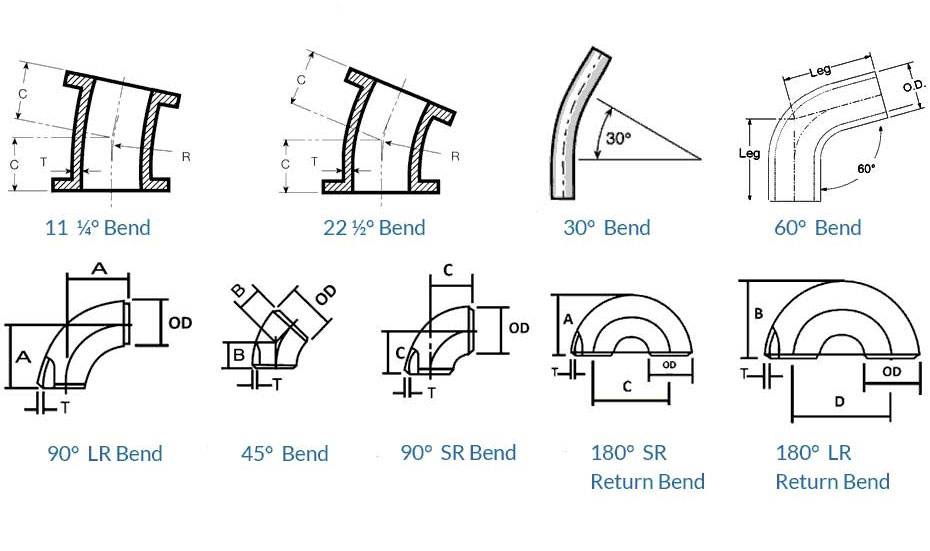

Carbon Steel Piggable Bend Types

Carbon Steel Pipe Bend

Carbon Steel Long Radius Pipe Bend

Carbon Steel Seamless Pipe Bend

Carbon Steel Welded Piggable Bend

Carbon Steel 3D Pipe Bend

Carbon Steel 6D Pipe Bend

Carbon Steel 10D Pipe Bend

Check Carbon Steel Piggable Bends, Price List, Sizes and Dimensions.

Radius Table of ASTM A234 CS WPB Seamless Piggable Bends

| Standard pipe | Spec | . Bauart 5 | 2,5D | |

|---|---|---|---|---|

| DN | Diameter [ØD] | CLR | CLR | CLR |

| 20 | 26,9 | 110 | 67 | |

| 25 | 33,7 | 110 | 84 | |

| 32 | 42,4 | 110 | 106 | |

| 40 | 48,3 | 110 | 212 | |

| 50 | 60,3 | 125 | 151 | |

| 65 | 76,1 | 175 | 190 | |

| 80 | 88,9 | 205 | 222 | |

| 100 | 114,3 | 270 | 286 | |

| 125 | 139,7 | 330 | 350 | |

| 150 | 168,3 | 390 | 421 | |

| 200 | 219,1 | 510 | ||

| 250 | 273 | 650 | ||

| 300 | 323,9 | 775 | ||

| 350 | 355,6 | 850 | ||

| 400 | 406,4 | 970 | ||

| 500 | 508 | 1245 | ||

| We Manufacturer ASTM A234 Gr WP9 Piggable Elbow as per ASME B16.69/ B16.9 Standard. | ||||

Carbon Steel 16 Gauge Piggable Bend Radius

| Gauge | Piggable Bend Radius Includes Minimum Closeness of Cutout to Bend |

Piggable Bend Radius (Refers to Inner Radius) |

| 11 gauge (0.120" |3.05mm) | .5" | .07", .08", .09", .1", .125" |

| 14 gauge (0.075" | 1.9 mm) | .275" | .05", .055", .062", .07", .075" |

| .375" | .07", .105" | |

| .5" | .09", .11", .115", .12" | |

| 1.375" | .4" | |

| 16 gauge (0.060" | 1.52 mm) | .2" | .035", .05" |

| .265" | .05", .055", .075", .08" | |

| .375" | .07" | |

| .5" | .105", .12" | |

| 18 gauge (0.048" | 1.22 mm) | .2" | .04", .045", .05" |

| .265" | .06", .07", .08", .085" | |

| .375" | .1", .125" | |

| .5" | .115", .12" | |

| 20 gauge (0.035" | 0.89 mm) | .2" | .05" |

| .265" | .06", .07" | |

| .375" | .095" | |

| 22 gauge (0.029" | 0.74 mm) | .2" | .05" |

| .265" | .04", .08" | |

| 24 gauge (0.024" | 0.61 mm) | .2" | .04" |

| .265" | .08" |

Carbon Steel Piggable Bend Radius Chart

| Standard pipe | Spec | . Bauart 5 | 2,5D | |

|---|---|---|---|---|

| DN | Diameter [ØD] | CLR | CLR | CLR |

| 20 | 26,9 | 110 | 67 | |

| 25 | 33,7 | 110 | 84 | |

| 32 | 42,4 | 110 | 106 | |

| 40 | 48,3 | 110 | 212 | |

| 50 | 60,3 | 125 | 151 | |

| 65 | 76,1 | 175 | 190 | |

| 80 | 88,9 | 205 | 222 | |

| 100 | 114,3 | 270 | 286 | |

| 125 | 139,7 | 330 | 350 | |

| 150 | 168,3 | 390 | 421 | |

| 200 | 219,1 | 510 | ||

| 250 | 273 | 650 | ||

| 300 | 323,9 | 775 | ||

| 350 | 355,6 | 850 | ||

| 400 | 406,4 | 970 | ||

| 500 | 508 | 1245 | ||

Piggable Bend Material thickness from 1.5 to 12.5 mm - in some cases up to 20 mm. CLR = Centre Line Radius for bend.

| Nominal pipe size | Outside Diameter at Bevel | Center to End | |||

| D | C | M | |||

| DN | INCH | Series A | Series B | ||

| 15 | 1/2 | 21.3 | 18 | 25 | |

| 20 | 3/4 | 26.9 | 25 | 29 | |

| 25 | 1 | 33.7 | 32 | 38 | |

| 32 | 11/4 | 42.4 | 38 | 48 | |

| 40 | 11/2 | 48.3 | 45 | 57 | |

| 50 | 2 | 60.3 | 57 | 64 | |

| 65 | 21/2 | 76.1(73) | 76 | 76 | |

| 80 | 3 | 88.9 | 89 | 86 | |

| 90 | 31/2 | 101.6 | ― | 95 | |

| 100 | 4 | 114.3 | 108 | 105 | |

| 125 | 5 | 139.7 | 133 | 124 | |

| 150 | 6 | 168.3 | 159 | 143 | |

| 200 | 8 | 219.1 | 219 | 178 | |

| 250 | 10 | 273.0 | 273 | 216 | |

| 300 | 12 | 323.9 | 325 | 254 | |

| 350 | 14 | 355.6 | 377 | 279 | |

| 400 | 16 | 406.4 | 426 | 305 | |

| 450 | 18 | 457.2 | 478 | 343 | |

| 500 | 20 | 508.0 | 529 | 381 | |

| 550 | 22 | 559 | ― | 419 | |

| 600 | 24 | 610 | 630 | 432 | |

| 650 | 26 | 660 | ― | 495 | |

| 700 | 28 | 711 | 720 | 521 | |

| 750 | 30 | 762 | ― | 559 | |

| 800 | 32 | 813 | 820 | 597 | |

| 850 | 34 | 864 | ― | 635 | |

| 900 | 36 | 914 | 920 | 673 | |

| 950 | 38 | 965 | ― | 711 | |

| 1000 | 40 | 1016 | 1020 | 749 | |

| 1050 | 42 | 1067 | ― | 762 | 711 |

| 1100 | 44 | 1118 | 1120 | 813 | 762 |

| 1150 | 46 | 1168 | ― | 851 | 800 |

| 1200 | 48 | 1220 | 1220 | 889 | 838 |

Looking for Carbon Steel Piggable Bends manufacturer in India? buy from oldest CS Piggable Pipe Bends manufacturers in Mumbai. Check Carbon Steel Piggable Bends Specification, Carbon Steel 180 Deg. Piggable Pipe Bends & Butt Weld 2.5D Piggable Bends Supplier

Specialized in Following ASME B16.9 Carbon Steel Piggable Bends

- ANSI B16.9 Carbon Steel A234 Butt weld Piggable Bend

- Carbon Steel ASTM A234 WPB Piggable Bends

- High Yield CS ASTM A860 Buttweld Piggable Bend

- Carbon Steel Industrial Piggable Bends

- MSS SP-43/SP-75 LTCS WPL3 LR Piggable Bend

- ANSI B16.28 High Yield WPHY X46 CS Piggable Bend

- High Yield CS A860 Piggable Pipe Bends

- Stockist of Carbon Steel Piggable Bend

- CS A234 WPB Piggable Bend Supplier

- Carbon Steel Piggable Bend ANSI B16.9

- ASTM A420 Low Temperature Steel Piggable Bends

- ANSI B16.9 Carbon Steel 5D BW Piggable Bends

- 24 Inch Carbon Steel Long Radius 180° Piggable Bend

- Carbon Steel SCH 40 Seamless 45° Piggable Bend

- High Yield CS X42 45 Degree Piggable Bend

- Carbon Steel Piggable Bends Manufacturers in India

- Carbon Steel 10D Piggable Bends Dealer

- Carbon Steel 3D Piggable Bends

- Carbon Steel LR Piggable Bends

- Supplier of CS Buttweld Piggable Bend

- Exporter of Carbon Steel Piggable Bends

- CS 12D Piggable Bend Supplier in India

- 180 Degree Piggable Bends Manufacturer in India

- Carbon Steel EN Piggable Bends

- Carbon Steel Small Size Piggable Bend Wholesaler

- Carbon Steel Buttweld 90 Degree Piggable Bends

- A860 High Yield Carbon Steel Piggable Bend Suppliers

- Carbon Steel 8D Piggable Bends

Carbon Steel Piggable Bends

Carbon Steel Buttweld Pipe Piggable Bends Price List

| Wholesale carbon steel piggable bends | US $5.00-$200.00 / Piece (FOB Price) |

| 3d/5d asme b16.49 seamless carbon steel Piggable bends | US $2.00-$400.00 / Piece (FOB Price) |

| 45 degree or 90 degree Carbon Steel Piggable Bends | US $2.00-$250.00 / Ton (FOB Price) |

| ANSI B16.9 carbon steel Piggable bends | US $0.40-$20.00 / Piece (FOB Price) |

| ASTM Butt-welded carbon steel Piggable pipe bends | US $400.00-$550.00 / Ton (FOB Price) |

| asme standard seamless carbon steel Piggable bends | US $50.00-$75.00 / Pieces (FOB Price) |

| ASME B16.9 3D 5D 90 Degree Black Carbon Steel 12 inch Piggable Bend | US $62.00-$85.00 / Pieces (FOB Price) |

| Low Temperature Carbon Steel WPL6 3D Piggable Bend | US $2.00-$200.00 / Piece (FOB Price) |

| Low Temperature Steel Carbon Steel WPL6 Piggable Bends | US $2.00-$300.00 / Piece (FOB Price) |

| 180 degree seamless 5d carbon steel Piggable pipe bends | US $20.00-$200.00 / Piece (FOB Price) |

Are you in search of a reliable manufacturer of Carbon Steel Piggable Bend in Mumbai, India? We offer high-quality CS Customized Piggable Bends at competitive prices.

Carbon Steel Piggable Bend Manufacturing Process