Carbon Steel ASTM A105 Forged Cap

- home

- Carbon Steel

A105 Cap, ASME SA105N Pipe Cap, ASTM A105 Carbon Steel Forged Cap, A105 Forged End Cap, CS SA105 Threaded Cap, ASTM A105 Socket Weld Cap, ASTM A105 Carbon Steel Cap Manufacturers in India.

Rajdhan Metal is well-known for providing high-quality Carbon Steel A105 Forged Cap in a timely manner. One of the most useful fittings is a cap. They come in a variety of forms and are used as pipe end protection devices. The ASTM A105 Cap adheres to strict industrial requirements and is utilised in high-temperature applications in pressure systems. The ASTM A105 Cap is primarily used to waterproof connections and close the pipe and tube end. Whatever the form of the pipe, we have designed the end cap to fit. The A105 Carbon Steel Cap, for example, is suited for use on round-ended pipes and tubes.

- What is A105 Steel Cap?

- ASTM A105 Carbon Steel Cap Specification

- ASTM A105 Carbon Steel Pipe Cap Types

- ASTM A105 Cap Dimensions

- CS Forged ASTM A105 Cap Pressure Rating

- Specialized in Following ASME B16.11, SA105 Forged Carbon Steel Cap

- Forged Carbon Steel ASTM A105 Cap Price

- ASTM A105 Forged Cap Price List In India

- Forged ASTM A105 Carbon Steel Cap Weight Chart

- ASME SA105N Cap Industrial Applications

ASME SA 105 Forged Carbon Steel Cap Suppliers, ASME SA 105 Forged Steel Cap, Supplier of ASTM A105 End Pipe Cap, Forged ASTM A105 Steel Cap Manufacturer in Mumbai, Carbon Steel A105 Cap, A105N End Cap.

What is A105 Cap?

Carbon Steel Forged Caps Fittings are primarily intended for usage as a pipe connection or pipe

junction. CS A105 Forged Caps are commonly used in gravity-fed low and high-pressure systems.

We are committed to providing high-quality items. We make Carbon Steel A105 Forged Cap with high-quality carbon steel to ensure its durability and longevity. Our CS A105 Forged Cap is corrosion resistant and may be utilised in a variety of applications. We also make certain that the items are delivered on time to our client's homes. We are one of the largest stockists and suppliers of CS ASTM A105 Forged Cap, and clients can expect innovative items at a reasonable price when they come to us.

Application and Uses of Carbon Steel A105 Forged Cap:

- Carbon Steel A105 Forged Cap is utilized In Fire Fighting.

- These Forged caps have a usage in Mechanical, electrical, and plumbing applications.

- The Carbon Steel A105 Forged Cap is also used in The Construction Industry.

- Carbon Steel A105 Forged Cap is used in HVAC systems (heating, ventilation, and air conditioning).

- Carbon Steel A105 Forged Cap has applications in Fluid Piping.

ASME B16.11 High Pressure SA105 Carbon Steel Pipe End Cap Exporter, Carbon Steel Cap, ASTM A105 CS Round Cap, Manufacturer of Carbon Steel ASTM A105 Cap in Mumbai, India.

ASTM A105 Carbon Steel Cap Specification

| Specifications | ASTM A105, ASME SA 105 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Thread | NPT, BSPT, BSPP |

| Connection | Socket Welded (male or female), Screwed-Threaded Fittings |

| Types of Cap in Piping | Threaded Cap, Socket Weld Cap, End Cap, Pipe Cap |

| Pressure Rating | Threaded Forged Pipe Fittings: 2000LBS, 3000LBS, 6000LBS Socket welding 3000, 6000, 9000 LBS |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | Socket Weld and Threaded Pipe Fittings, 90 deg Elbows, Cross, Inserts, and Unions, Caps, 45 degree Elbows, Nipples, Couplings, Tees, Plugs, Equal Tees, Reducing Tees |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Types of ASTM A105 Carbon Steel Forged Cap

Carbon Steel A105N Round Caps

Carbon Steel ASME SA105 Cap

View the dimension and weight chart for A/SA105N NPT black steel caps, in accordance with ASME B16.11 standards

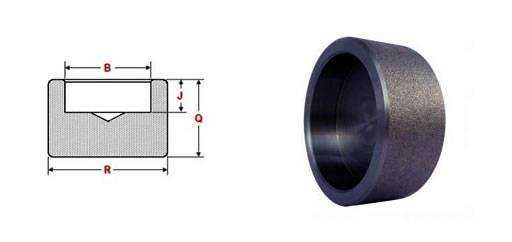

ASTM A105 Forged Cap Dimensions

- Standard: ASME B16.11 or MSS SP-79

- Cap Size : 1/8" to 4"

- Pressure rating: 2000#, 3000#, 6000#, 9000#

- End connections: Socket Weld, Threaded

ASTM A105 Socket Weld Cap Dimensions

| (NPS) Normal Pipe Size | Socket Bore | Depth Of Socket | Length Of ASTM A105 Pipe Cap | Socket Cap Diameter |

| B | J | Q | R | |

| 1/2 | 21.95 21.70 |

10 | 19 | 32 |

| 3/4 | 27.30 27.05 |

13 | 23 | 38 |

| 1 | 34.05 33.80 |

13 | 26 | 45 |

| 1.1/4 | 42.80 42.55 |

13 | 28 | 55 |

| 1.1/2 | 48.90 48.65 |

13 | 30 | 65 |

| 2 | 61.35 61.10 |

16 | 36 | 75 |

| 2.1/2 | 74.20 73.80 |

16 | 38 | 92 |

| 3 | 90.15 89.80 |

16 | 42 | 110 |

| 4 | 115.80 115.45 |

19 | 48 | 140 |

ASTM A105 Threaded Cap Dimensions

| NPS | End to End | O.D. (Outside Diameter) | Min. End Wall Thick. | Minimum Thread Length | |

| A | D | G | B | J | |

| 1/2 | 32 | 28 | 6.4 | 10.9 | 13.6 |

| 3/4 | 37 | 35. | 6.4 | 12.7 | 13.9 |

| 1 | 41 | 44 | 9.7 | 14.7 | 17.3 |

| 1.1/4 | 44 | 57 | 9.7 | 17 | 18 |

| 1.1/2 | 44 | 64 | 11.2 | 17.8 | 18.4 |

| 2 | 48 | 76 | 12.7 | 19 | 19.2 |

| 2.1/2 | 60 | 92 | 15.7 | 23.6 | 28.9 |

| 3 | 65 | 108 | 19 | 25.9 | 30.5 |

| 4 | 68 | 140 | 22.4 | 27.7 | 33 |

CS Forged ASTM A105 Cap Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

Rajdhan Metal offers high-quality carbon steel forged caps for pipe connections, with pressure ratings of class 3000 or 6000, at competitive prices.

Specialized in Following ASME B16.11, SA105 Forged Carbon Steel Cap

- Carbon Steel ASTM A105 BSP Cap

- A105 High Pressure Carbon Steel Forged Cap

- Manufacturer of A105 Cap

- Steel Forged ASTM A105 Cap Supplier in India

- Carbon Steel A105 Forged High Pressure Pipe Cap

- Class 6000, 2 Inch, ASTM A105 Cap

- Steel A105 Forged Cap Wholesaler

- Carbon Steel A105 Female Threaded Cap

- Carbon Steel Forged A105 NPT Cap

- Supplier of A105N CS NPT Threaded Cap

- Exporter of A105 Threaded Carbon Steel Forged Cap

- Manufacturer of Carbon A105 Threaded End Cap

- Class 3000, 2 Inch A105 Carbon Forged Steel Cap

- ASTM A105 Forged Cap Manufacturer in India

- A105 Forged Steel Cap Supplier

- ASTM A105 Cap Suppliers

- 1 NPS, ASME SA105 Carbon Steel Cap

- Carbon Steel A105 BSP Threaded Forged Cap Dealer

- CS ASME SA105N 2 in. 6000# Threaded NPT Cap

- 1 1/4 NPS, SW End, SA105 CS Cap

- ASTM A105 Socket Weld Pipe Cap

- Carbon Steel A105 NPT Threaded End Cap

- FNPT End, 3000#, 1/2 NPS, A105N Cap

- Class 3000, 1 1/3 Inch ASTM A105 Cap

- Buy SA 105N Socket Weld Carbon Steel Forged Cap

- ASTM A105N 3000lbs NPT Cap

- Carbon SA105 Male Threaded Cap

- Carbon Steel A105 BSP Cap

- Carbon Steel ASTM A105 Screwed Cap Suppliers

- Carbon Steel ASTM A105N Threaded Screw Cap

- Forged Carbon Steel A105 Screwed Cap

- 2000 LB, 1 1/2 Inch ASTM A105 Cap

- Carbon Steel Forged A105 High Pressure Cap

- ASTM A105 Cap Manufacturer

- Stockists of SA 105 Forged Steel BSPT Cap

- Forged Steel ASTM A105 Carbon Cap

- Forged Carbon Steel ASTM A105 Industrial Cap

- SA 105 Galvanized Carbon Steel Forged Cap

- Carbon Steel A105 Forged Cap

- ASME B16.11 Carbon Steel SA105 Threaded Cap

Forged Carbon Steel Cap

Forged Carbon Steel ASTM A105 Cap Price

|

|

ASTM A105 Forged Cap Price List In India

| Size | Class | Grade | Type Of Forged Cap | Price In INR (Per Piece) |

| 1/3 NPS | Class 3000 | ASTM A105 | Socket Weld | 90.00 |

| 1 NPS | Class 3000 | ASTM A105 | Socket Weld | 180.00 |

| 2 NPS | Class 3000 | ASTM A105 | Threaded | 270.00 |

| 3 NPS | Class 3000 | ASTM A105 | Threaded | 340.00 |

ASTM A105 Carbon Steel Cap Weight Chart

| Type | Forged Socket Welding Fitting ANSI B16.11 - Classes 3000 - 6000 - 9000 LBS Weight (kg) |

|||||||||||

| Caps | Class | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1 ¼" | 1 ½" | 2" | 2 ½" | 3" | 4" |

| 3000 | 0.035 | 0.060 | 0.135 | 0.175 | 0.295 | 0.510 | 0.650 | 0.920 | 1.40 | 2.50 | 3.50 | |

| 6000 | 0.075 | 0.135 | 0.180 | 0.210 | 0.460 | 0.700 | 0.885 | 1.20 | 2.00 | 3.25 | 5.50 | |

| 9000 | 0.235 | 0.280 | 0.600 | 0.880 | 1.10 | 1.60 | ||||||

| Type | Forged Screwed-Threaded Fitting ANSI B16.11 - Classes 2000 - 3000 - 6000 LBS Weight (kg) |

|||||||||||

| Caps | Class | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1 ¼" | 1 ½" | 2" | 2 ½" | 3" | 4" |

| 3000 | 0.047 | 0.058 | 0.125 | 0.210 | 0.370 | 0.600 | 0.730 | 1.10 | 2.31 | 3.00 | 4.50 | |

| 6000 | 0.160 | 0.200 | 0.290 | 0.395 | 0.700 | 1.10 | 1.35 | 2.10 | 3.50 | 4.80 | 7.50 | |