Carbon Steel A105 Forged Tee

Carbon Steel ASTM A105 Forged Tee provides a tough and adaptable connector that is made up of an iron-carbon alloy containing sulfur, manganese, phosphorus silicon, and other metals to ward off corrosion and provide rigidity and strength for the petroleum gas, petrochemical and other industries.

A105 Carbon Steel Tee is used to connect or split pipes. Resembling the letters "T," our Tees are usually connected at 90 degree angle between pipes. As India's most reputable manufacturer and supplier of carbon steel forged tees, we specialize in socket weld and threaded tees at the most affordable prices.

ASTM A105 Socket Weld Tees, Buy ASME SA105N Threaded Reducing Tee at Best Price, ASTM A105 Carbon Steel Tee Manufacturers in India.

- ASTM A105N Tee Material Specification

- Forged Carbon Steel ASTM A105 Tee Price List

- Types of ASTM A105 Carbon Steel Tee

- ASTM A105 Forged Tee Dimensions

- CS Forged ASTM A105 Tee Pressure Rating

- Specialized in Following SA105 Carbon Steel Tee

- ASTM A105 Carbon Steel Tee Weight Chart

- ASME SA105N Tee Industrial Applications

Our A105 Socket Weld Equal Tee is used in a wide range of industries. It was designed to meet the most stringent standards and uses cutting-edge technology. Rajdhan Metal stands out as one of the best carbon steel socket weld tees tailored for pipes with a smaller diameter (NPS 2 or less).

We also excel in manufacturing ASTM A105N Threaded Tee, a popular choice for pipe fittings. It comes in different sizes and finishes. Our inventory also boasts a large stock of ASTM A105 Carbon Steel Reducing Tee, which is widely used to reduce the run ports between pipes. We also specialize in supplying and exporting ASTM A105 Forged Tee with Buttweld Pipe Fitting branches at a 45-degree angle to the pipeline.

We also excel in manufacturing ASTM A105N Threaded Tee, a popular choice for pipe fittings. It comes in different sizes and finishes. Our inventory also boasts a large stock of ASTM A105 Carbon Steel Reducing Tee, which is widely used to reduce the run ports between pipes. We also specialize in supplying and exporting ASTM A105 Forged Tee with Buttweld Pipe Fitting branches at a 45-degree angle to the pipeline.

To ensure high quality, we offer a variety of tests such as hardness and positive materials tests, intergranular testing for corrosion mill tests and chemical Spectro testing. These tests ensure quality.

When looking to buy carbon steel ASTM A105 forged tees, Rajdhan Metal offers high-quality products at the best price, with availability near Mumbai, India, and as a trusted supplier, all your large-scale and high-pressure application needs will be met with exceptional service and support.

ASTM A105N Tee Material Specification

| Specifications | ASTM A105 , ASME SA 105 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Thread | NPT, BSPT, BSPP |

| Connection | Socket Welded (male or female), Screwed-Threaded Fittings |

| Types of Tee in Piping | Threaded Tee, Socket Weld Tee, Equal Tee, Unequal Tee, |

| Pressure Rating | Threaded Forged Pipe Fittings: 2000LBS, 3000LBS, 6000LBS Socket welding 3000, 6000, 9000 LBS |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | Socket Weld and Threaded Pipe Fittings, 90 deg Elbows, Cross, Inserts, and Unions, Caps, 45 degree Elbows, Nipples, Couplings, Tees, Plugs, Equal Tees, Reducing Tees |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

The best manufacturer of ASTM A105 tee in Mumbai, India. For the final ASME SA105 forged steel Tee price list, please call (+91) 9892523354 or email [email protected]

ASME SA 105 Reducing Tee Suppliers, PED Approved A105N Carbon Steel Equal Tee, Dimensions ASTM A105 CS Forged Tees in KG.

Forged Carbon Steel ASTM A105 Tee Price List

|

|

Types of ASTM A105 Carbon Steel Tee

Check Price List and Dimensions of Black Steel A/SA105N NPT Tees.

ASTM A105 Forged Tee Dimensions

The size of an astm a105 forged tee can change depending on a number of variables, including the pipe's diameter, wall thickness, and size. these fittings typically come in sizes that range from 1/8 inch to 4 inches, and they may have wall thicknesses that are identified by a schedule number. the dimensions of an astm a105 forged carbon steel tee can also change based on the connection style, such as a socket weld, threaded connection, or a reducing tee.

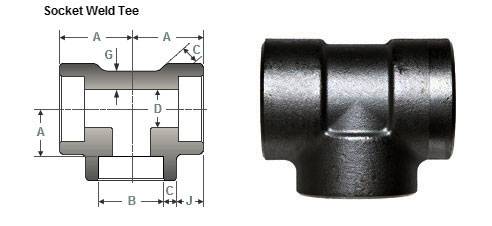

ASTM A105 Socket Weld Tee Dimensions

Class 3000 Socket Weld Tee Dimensions NPS 1/2 to 4

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

Class 6000 Socket Weld Tee Dimensions NPS 1/2 to 2

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

CS ASTM A105 Socket Weld Reducing Tee Dimensions

| (NPS) Normal Pipe Size | Socket Weld Bore | Depth Socket Weld | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

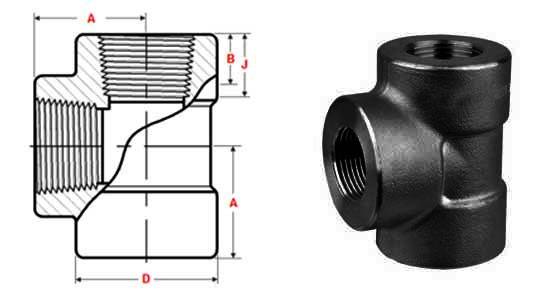

ASTM A105 Threaded Tee Dimensions

3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 2000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Equal Tee Class 3000 Dimensions NPS 1/2 to 4

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 6000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

ASME SA 105 Threaded Reducing Tee Dimensions

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

CS Forged ASTM A105 Tee Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

Looking for astm a105 forged screwed Tee with BSPT or NPT connections? Rajdhan Metal is a renowned manufacturer and stockist of carbon steel asme sa105n male and female Tee, available in class 3000 or 6000 pressure ratings. Contact us for the best prices and a free quote.

Specialized in Following SA105 Carbon Steel Tee

- Supplier of A105N CS NPT Threaded Pipe Tees

- Carbon Steel A105 BSP Threaded Forged Tees Dealer

- Exporter of ASTM A105 Threaded Carbon Steel Forged Tee

- Carbon Steel A105 Forged High Pressure Tees

- A105 Forged Steel Tees Supplier

- A105 High Pressure Carbon Steel Forged Tee

- Class 6000, 2 Inch, ASTM A105 Tee

- Manufacturer of Forged Carbon Steel A105 Tees

- 1 1/4 NPS, SW End, SA105 CS Tee

- Class 3000, 2 Inch A105 Carbon Forged Steel Tees

- ASTM A105 Forged Tees Manufacturer In India

- Steel A105 Forged Tee Wholesaler

- Manufacturer of A105 Tees

- 1 NPS, ASME SA105 Carbon Steel Tee

- Carbon Steel A105 Female Threaded Tee

- Carbon Steel ASTM A105 BSP Tees

- CS ASME SA105N Class 6000 Threaded Pipe Tees

- Carbon Steel Forged A105 NPT Tee

- Steel Forged ASTM A105 Tee Supplier in India

- ASTM A105 Tee Suppliers

- Buy SA 105N Socket Weld Carbon Steel Forged Tee

- Carbon Steel ASTM A105 Screwed Tees Suppliers

- Forged Carbon Steel ASTM A105 Industrial Tees

- ASTM A105 Tee Manufacturer

- Carbon Steel A105 Class 6000 Forged Tees

- ASME B16.11 Carbon Steel SA105 Threaded Tee

- Carbon Steel A105 NPT Threaded Reducing Tee

- SA 105 Galvanized Carbon Steel Forged Tee

- ASTM A105N 3000lbs NPT Tees

- FNPT End, 3000#, 1/2 NPS, A105N Tee

- 2000 LB, 1 1/2 Inch ASTM A105 Tee

- Carbon Steel A105 BSP Tees

- Class 3000, 1 1/3 Inch ASTM A105 Tee

- Carbon SA105 Male Threaded Tee

- Stockists of SA 105 Forged Steel BSPT Tee

- Forged Steel ASTM A105 Carbon Tee

- ASTM A105 Socket Weld Pipe Tees

- Forged Carbon Steel A105 Screwed Tees

- Carbon Steel Forged A105 High Pressure Tees

- Carbon Steel ASTM A105N Reducing Tee

Forged Carbon Steel Tee

ASTM A105 Carbon Steel Tee Weight Chart

| DN SIZE | CLASS 3000 (Socket Weld) | DN SIZE | CLASS 6000 (Socket Weld) | ||

| Tee | Tee | ||||

| kg | Lb | kg | Lb | ||

| 1/2 | .29 | .62 | 1/2 | .56 | 1.18 |

| 3/4 | .42 | .88 | 3/4 | .94 | 1.93 |

| 1 | .65 | 1.30 | 1 | 1.49 | 3.10 |

| 1 1/4 | 1.04 | 2.00 | 1 1/4 | 1.93 | 4.22 |

| 1 1/2 | 1.35 | 2.99 | 1 1/2 | 3.37 | 7.59 |

| 2 | 2.04 | 4.60 | 2 | 3.95 | 8.70 |

| 2 1/2 | 3.98 | 8.49 | 2 1/2 | 6.90 | 15.09 |

| 3 | 5.90 | 13.85 | 3 | 11.48 | 25.24 |

| DN SIZE | CLASS 3000 (Threaded) | DN SIZE | CLASS 6000 (Threaded) | ||

| Tee | Tee | ||||

| kg | Lb | kg | Lb | ||

| 1/2 | .56 | 1.20 | 1/2 | .98 | 2.21 |

| 3/4 | .92 | 1.87 | 3/4 | 1.65 | 3.57 |

| 1 | 1.49 | 2.95 | 1 | 2.17 | 5.11 |

| 1 1/4 | 1.76 | 3.92 | 1 1/4 | 3.74 | 8.25 |

| 1 1/2 | 3.27 | 7.35 | 1 1/2 | 4.71 | 10.46 |

| 2 | 3.53 | 7.58 | 2 | 7.88 | 17.54 |

| 2 1/2 | 6.99 | 14.61 | 2 1/2 | 13.11 | 30.65 |

| 3 | 10.19 | 22.82 | 3 | 22.50 | 49.50 |

Looking for a trustworthy Mumbai-based manufacturer of carbon steel a105 tee in India? Our company provides a wide stock of a105 forged steel tees at affordable rates.