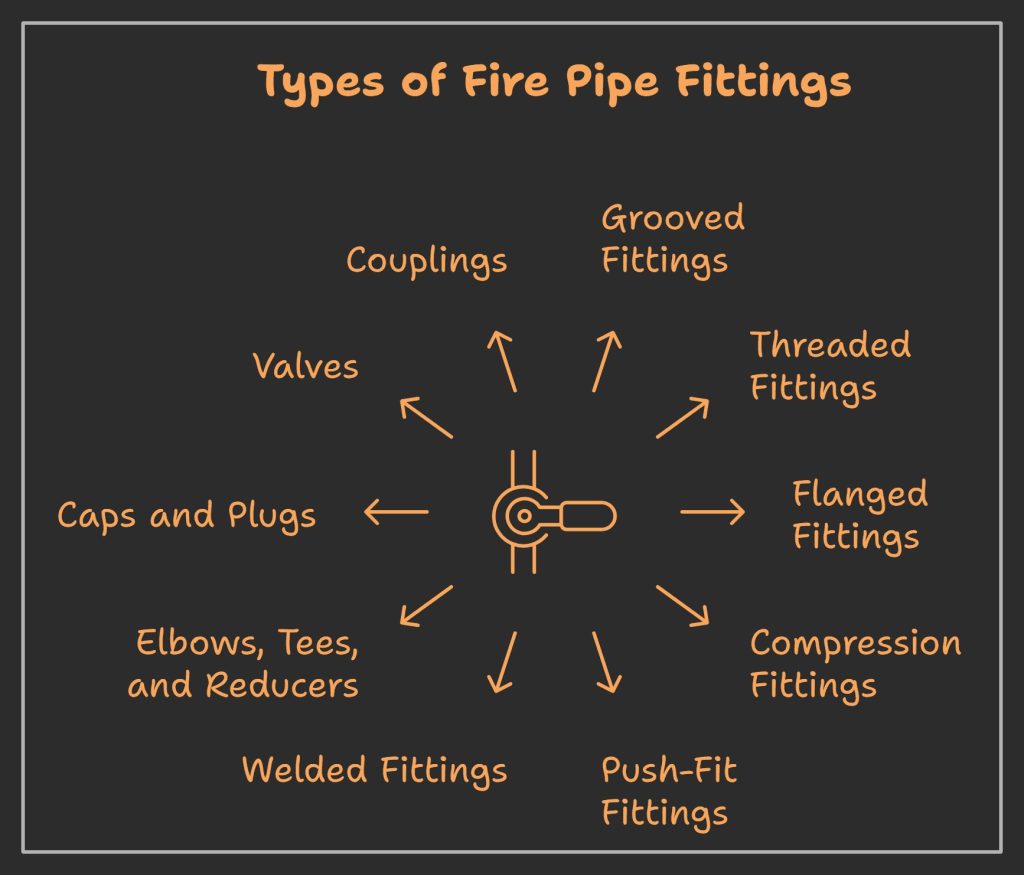

Fire pipe fittings are those parts employed in Fire protection systems to join, regulate and guide the passage of water or Other fire extinguishing mediums through pipes. These fittings aid the fire sprinkler and hydrant systems performing their tasks in houses as well as industries. Fire pipe fittings are supposed to qualify pressures and conditions and support the fire protection system so as to ensure the reliability in human and material lives during accidents.

In the case of fire safety, the reliability of the fire protection system is defined with reference to quality and variety of fittings. Fire pipe fittings are not just connectors; they are the critical links for the disparate parts of a fire protection system; Guaranteeing the water or fire-suppressant is where it has to go when milliseconds matter. Below is one of the most comprehensive lists that show the fire pipe fittings and each of them with some explanations of the role they play to ease your decision-making process.

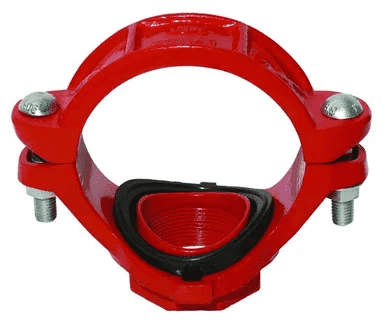

1. Grooved Fittings

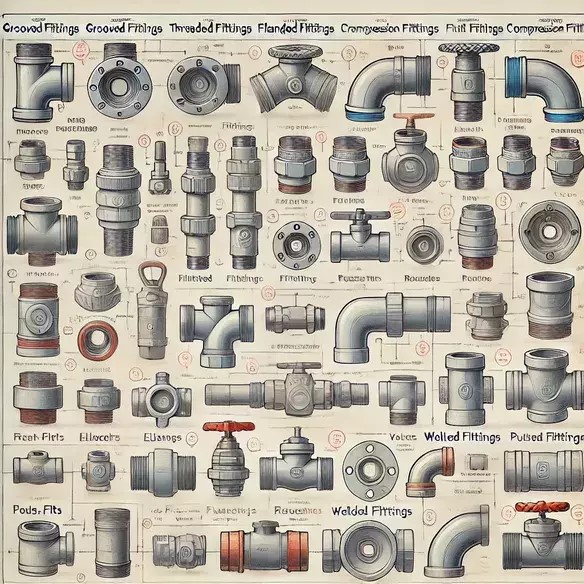

Grooved fittings are generally preferred in the industry due to their simple rather than installation and ease of maintenance. Unlike typical courses which are threaded or welded these fittings incorporate a gasket that clamps pipes in place. This design is minimally invasive and one of the best suited for large multi-scheme fire protection systems since it is easier to install the system leaving minimal space for interferences while making it easier to access the system and fix or replace parts that may have degraded over time.

Benefits: Easy to build quickly, it allows for access for repair work, and during thermal expansion slight movement is permitted.

Ideal For: Huge shops or Industries where HUGE sprinklers network system is fitted.

2. Threaded Fittings

Threaded fittings have been in the market for a long time and are considered leading fire pipe fittings. Fire threaded fittings give assurance that pipes can be connected strongly to each other since it allows pipes to be joined firmly. But, they take more time and space during installation, and if not well fixed, the water leakage tendency is high.

Benefits: Excellent for pressure-related applications due to the copious amounts of mechanical strength and durability that the present woven fabric connectors offer.

Ideal For: Other applications are where the smaller systems or places are, where pipes do not have to be disassembled frequently.

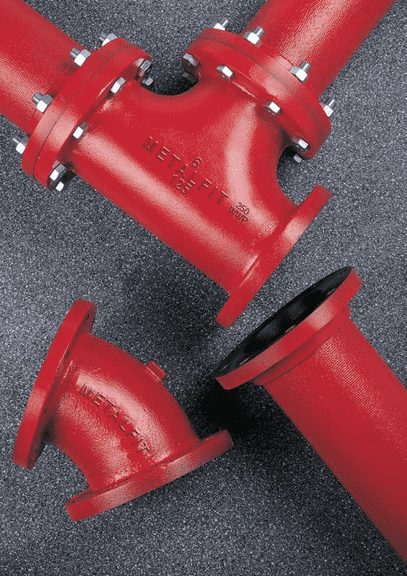

3. Flanged Fittings

While there is extensive application of flanged fittings, particularly where maintenance or inspection is frequently required. That is why they employ flanges, those are the round discs that are interlinked by bolts to provide a high quality and tight sealing connection. Being removable by means of a bolt and a nut flanged fittings are suitable for the parts of the system which require regular inspection or repair.

Benefits: Easily assembled, with provision for securing tight pressure .

Ideal For: Large fire protection systems with extensive service requirements, say a chemical plant or a refinery.

4. Compression Fittings

Compression fittings involve the use of a ring or ferrule that will always squeeze the pipe when a twist is made on it to seal the pipe. The design is fairly easy to implement since no specific instruments are needed to do that. Compression fittings are used in most residential plumbing applications, but also for fire sprinkler systems where it is necessary to install quickly.

Benefits: Simple to use, fast and takes no time to do, no need for welding or threading.

Ideal For: Portable and portable sprinkler systems, or as supplementary systems to existing ones.

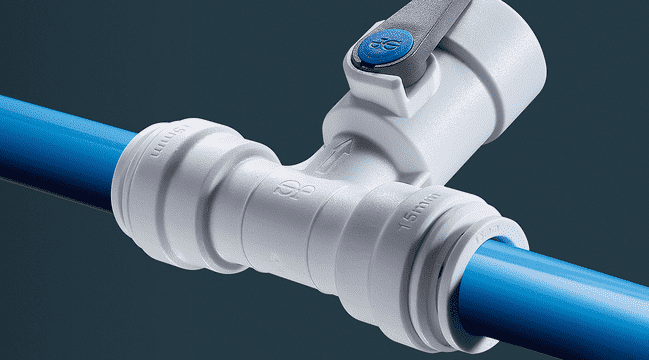

5. Push-Fit Fittings

Push-fit fittings are among the innovative products in the world of fire protection at the moment. Labeled in accordance with this principle, the technique means that the pipe is inserted into the fitting to form a tight assembly. This system does not need welding, threading or even tools and is therefore fast and convenient to use. Push-fit fittings are very nice for small or installation works where versatility is important.

Benefits: You really don’t need any other tools to install the furniture; the process of assembling the item is really fast.

Ideal For: Small-scale protection either for residential purposes or for small businesses.

6. Welded Fittings

Welded Fittings used in mainly fire protection system project or Project system where high pressure containing pipe system is required. These are fittings which are fixed directly to the pipe with a very strong and in most cases, such fittings cannot be unbolted from the pipe.

Benefits: Resilient, rigid, for high pressure use.

Ideal For: It has been used in industrial fire systems where some parts need to have extreme durability added to them.

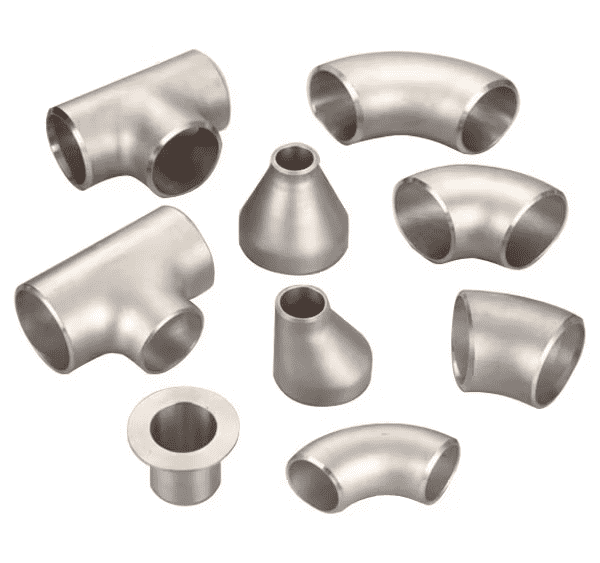

7. Elbows, Tees, and Reducers

These fittings, commonly categorized as “directional fittings,” are employed to manage the configuration of the FP system. Each serves a specific purpose:

Elbows: It is also feasible to alter the direction of the piping.

Tees: To improve the flow let the particular flow go into different branches.

Reducers: Alter the diameter of the pipe most of the time to enhance the pressure in some regions.

Hangers and drilled straps are important because they help to provide a decent pattern so water, or suppressant reaches every corner of the building.

Benefits: Flexible to complex layout features, guaranteeing smooth traffic within a system.

Ideal For: Any fire protection system especially for tall buildings or big complexes.

8. Caps and Plugs

End caps and plugs are another example of components that may not get as much consideration, nevertheless they have the critical job of fire system closure. Caps are used to shut the end of a pipe while plugs are used to block any useless outlets. Both leakage is prevented and pressure in the system is to be kept.

Benefits: Stop loss, conserve system pressure.

Ideal For: Situations which include areas can be able to accommodate the outlets but they are not utilized or sometimes certain areas of the building may be closed for sometime.

9. Valves

Valves enable you to regulate an amount of disbursement of water in the fire system. They are crucial when they are needed to close and divide parts where water is not needed or when working with different tests. Common types include:

Ball Valves: It just turns off promptly with no need for a long handing or messing around.

Gate Valves: Short lasting and gradual closure, suitable for applications requiring flow regulation.

Check Valves: Backflow prevention, making sure that water should be flowing in one particular direction.

Benefits: Valve operations, backflow prevention, sectionalization of a specific segment of a utility’s system.

Ideal For: Each type of fire protection system; essential for inspection and for security and other purposes.

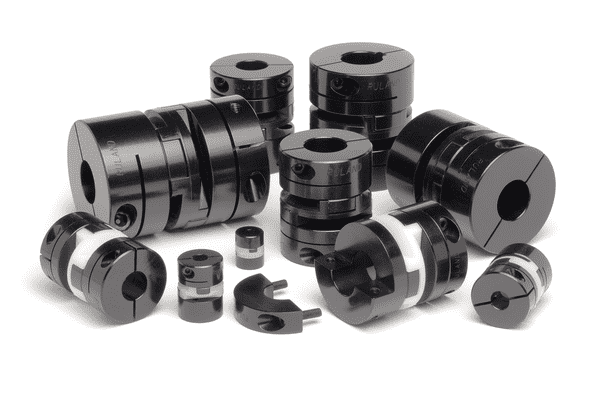

10. Couplings

Connecting pieces are used to ensure that two sections of pipe are well joined together. In fire protection systems, couplings are generally available in grooved or threaded form for ease of the two connecting methods. Such solutions can enhance the ease of getting the desired structural layout; besides, they act as stress buffers in case of thermal expansion or contraction.

Benefits: Readily adjustable, stress taking, convenient accessibility for maintenance.

Ideal For: Large systems that may experience shift of pipes or vibration.

Selecting Appropriate Fittings for Fire Fighting System

Are you looking for Best & Affordable Fire Pipe Fittings manufacturers in Mumbai? It is probable to note that different varieties of fire pipe fittings have different significance during the process of the installation as well as make your system more appropriate and easy to operate. It concerns choices made on which fittings to put in whether it is in a small compact system for a small business, whether it’s a setup for a factory; it matters because it can save lives and assets.