What are Fittings and Where Do You Use Them?

Fittings play a key role in plumbing and piping systems. They provide vital links and jobs to keep fluids flowing. But what are fittings, and where do you use them? In simple terms, fittings connect pipes. They change pipe directions or control flow in a piping system. Leaks can be avoided using the right fittings, maintaining water pressure, and improving general efficiency. Fittings for pipes come in various shapes, sizes, and materials. Each type suits a specific use in the pipeline. Take homes, for instance. Here, fittings join water supply lines. In factories, they handle high-pressure fluids used in making things.

Types of Fittings

Fittings are distinguished based on the connection types and functions they perform. Fittings are distinguished based on the connection types and functions they perform. They can be welded, threaded, mechanically joined, or chemically adhered, depending on the pipe material.

Pipe Fittings

Pipe fittings connect pipes of the same or different diameters to create a continuous, leak-free piping system. There are two main types: seamless fittings and welded fittings.

Seamless Fittings

Seamless fittings are manufactured without seams, making them ideal for high-pressure applications. For example, in an oil refinery, seamless elbows and tees are often used to handle high-pressure fluids without the risk of leaks. These fittings are crafted from a single piece of material, ensuring uniform strength and reliability.

Welded Fittings

Welded fittings, on the other hand, are made by welding pieces of material together. They are suitable for lower pressure applications compared to seamless fittings but offer more flexibility in size and shape. For instance, in a water treatment plant, welded fittings like reducers and crosses are commonly used to manage various piping configurations efficiently.

Forged Fittings

Forged fittings are strong pipe connectors that shape hot metal under high pressure. This process creates very durable fittings that can withstand extreme conditions. They’re commonly used in industries like oil and gas, where reliability is crucial. They are known for being strong and durable, making them suitable for high-pressure and high-temperature applications. They come in two primary types: socket weld and threaded fittings.

Socket Weld Fittings

Socket weld fittings involve inserting the pipe into a recessed area of the fitting and then welding around the top. This method provides a strong, leak-proof connection. For example, socket weld fittings in chemical plants ensure robust connections that can withstand aggressive chemicals.

Threaded Fittings

Threaded fittings, also known as screwed fittings, have screw threads on the inside or outside, allowing pipes to be screwed together. These fittings are commonly used in residential plumbing for easy assembly and disassembly. An example would be connecting water supply lines to a kitchen sink using threaded fittings. Common thread size standards include NPT (National Pipe Thread) and BSP (British Standard Pipe). These standards dictate the number of threads per inch (TPI) each fitting should have. Other thread standards can vary depending on the country and industry in which they are used.

Fire Pipe Fittings

These are specialized to ensure safety and efficiency in firefighting systems. In commercial buildings, fittings like fire hose reels and sprinkler heads are critical for delivering water efficiently during emergencies. Simpler fittings like smoke detectors connected to water sprinklers are used in residential buildings.

Branch Fittings

Branch fittings, or branch outlets, connect a branch pipe to a main run pipe.

For example, A weldolet is a small, reinforced fitting welded directly onto a larger pipe to create a branch connection. It’s like adding a small pipe stub to the side of a bigger pipe, allowing you to connect a smaller pipe at a right angle.

HVAC Fittings

HVAC systems require specific fittings to ensure efficient airflow and temperature control. For instance, a flexible duct connector fitting allows for easy installation of HVAC ducts, ensuring a secure and flexible connection.

Compression Fittings

Compression fittings are devices used to connect pipes or tubes securely without welding. They work by compressing a ring or ferrule tightly around the pipe as the fitting is tightened. This creates a strong, leak-proof seal that can withstand high pressure.

Groove Fittings

Groove fittings are often used in large piping systems for quick and easy assembly. They feature a groove around the pipe’s circumference that locks into place with a coupling commonly used in industrial water treatment plants.

Learn more on types of pipe joints

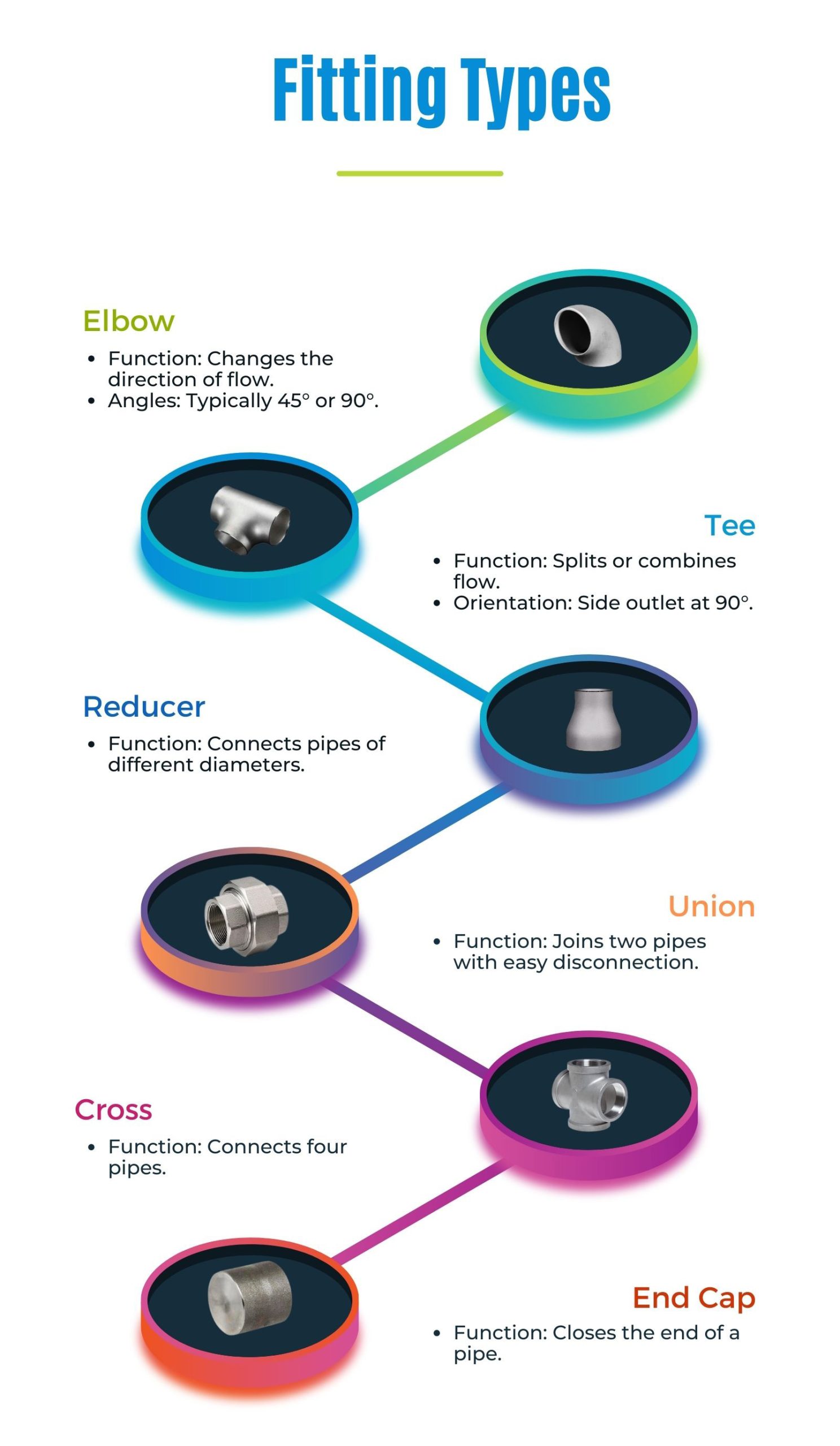

Different Options in Fitting Types

Elbow

Used to change the direction of the flow, typically by 45° or 90°.

Tee

Allows splitting or combining flow with a side outlet at 90° to the run of the pipe.

Reducer

Connects pipes of different diameters.

Union

Used to join two pipes and allow easy disconnection.

Coupling

Connects two pipes together.

Adapters

Used to connect pipes of different types.

Valve

Controls the flow of fluids.

Cross

Connects four pipes.

Cap

Used to close the end of a pipe.

Swage Nipple

A reducer used to join pipes of different diameters.

Plug

Closes off a pipe end.

Bush

Reduces the size of a fitting.

Expansion Joint

Allows for movement in the piping system.

Long Radius Bend

Used to change the direction with a longer radius.

Flanges

Provides a method of connecting pipes, valves, pumps, and other equipment.

Gasket

Seals flange joints to prevent leaks.

Collar

Joins two pipes of the same length

Fittings for Connecting Smaller Pipes

These fittings connect smaller-diameter pipes to larger ones, maintaining a seamless flow. An example is a reducer fitting, which allows different pipe sizes to connect smoothly, such as in a residential plumbing system where a 1-inch pipe needs to connect to a 1/2-inch pipe.

Fittings for Special Connections

Special fittings like tees and crosses provide multiple connections or specific functions. For instance, a tee fitting allows a single water supply to split into two directions, which is useful in distributing water to different house parts.

Fittings Which Extend or Terminate Pipe Lengths

Caps and couplings are used to extend or terminate pipe lengths. For example, a coupling can join two lengths of pipe, while a cap is used to terminate the end of a pipe, often seen in plumbing systems where future extensions might be planned.

Fittings that change pipe direction

Elbows, tees, crosses and bends change the direction of a piping system. For instance, a 90-degree elbow is commonly used in household plumbing to navigate corners or obstacles.

Materials Used for Fittings

- Cast Iron: Strong and highly abrasion-resistant, used for sanitary, storm drain, waste, and vent piping due to its resistance to abrasive materials.

- Carbon Steel: Due to its high density and wear resistance, this type is used in industrial applications, where high pressures and temperatures are typical.

- Mild Steel: Apart from being recommended for promoting various general applications, they include good weldability and machinability.

- Brass: Known for its corrosion resistance, it is often used in water supply lines.

- Stainless Steel is ideal for high-pressure and high-temperature applications, such as industrial chemical processes.

- PVC: Lightweight and corrosion-resistant, used in residential plumbing for waste and drainage systems.

Application of Fitting

There are diverse varieties of fittings applied in different industries for several purposes.

- Homes: Connecting water lines, drainage systems, and gas lines.

- Factories: Handling chemicals, gases, and high-pressure fluids.

- Fire Safety: Distributing water to fight fires.

- Water Supply: Linking sinks, showers, and toilets to the main water source.

- Wastewater: Routing waste away and preventing blockages.

- Gas Supply: Ensuring gas gets safely to stoves and heaters.

- Chemical Plants: Managing corrosive chemicals and high-pressure fluids.

- Oil and Gas: Handling high-pressure conditions in refineries and pipelines.

Selecting the Right Fitting

Choosing the right fitting involves understanding the requirements of your system and adhering to relevant standards.

Fitting Standards

Fitting standards are essential guidelines that ensure the safety and compatibility of piping systems. Organizations like ANSI, ASME, and ISO create these standards covering various fittings such as elbows and flanges. Important standards include the ASME/ANSI B16 series for dimensions and pressure ratings.

Following these standards, you can prevent leaks, ensure parts from different manufacturers fit together, and maintain quality in industries like oil and gas. Adhering to these standards is crucial for safe and efficient piping systems.

Read more on Fitting Standards.

In summary, fittings are vital components in any piping system, providing necessary connections and functions to ensure the smooth flow of fluids. Each type serves a specific purpose, from seamless welded fittings to specialized fire pipe fittings. Selecting the right fitting involves understanding the requirements of your system and adhering to relevant standards. With various materials available, fittings are tailored for diverse residential, industrial, and safety applications.